How are lab created diamonds made?

lab grown diamonds are identical to natural diamonds in every way, but are created in a controlled environment using cutting-edge technology, rather than the depths of the earth. And, if you’re wondering “do lab grown diamonds pass a diamond tester?” They absolutely do! They will test positive using any diamond testing method.

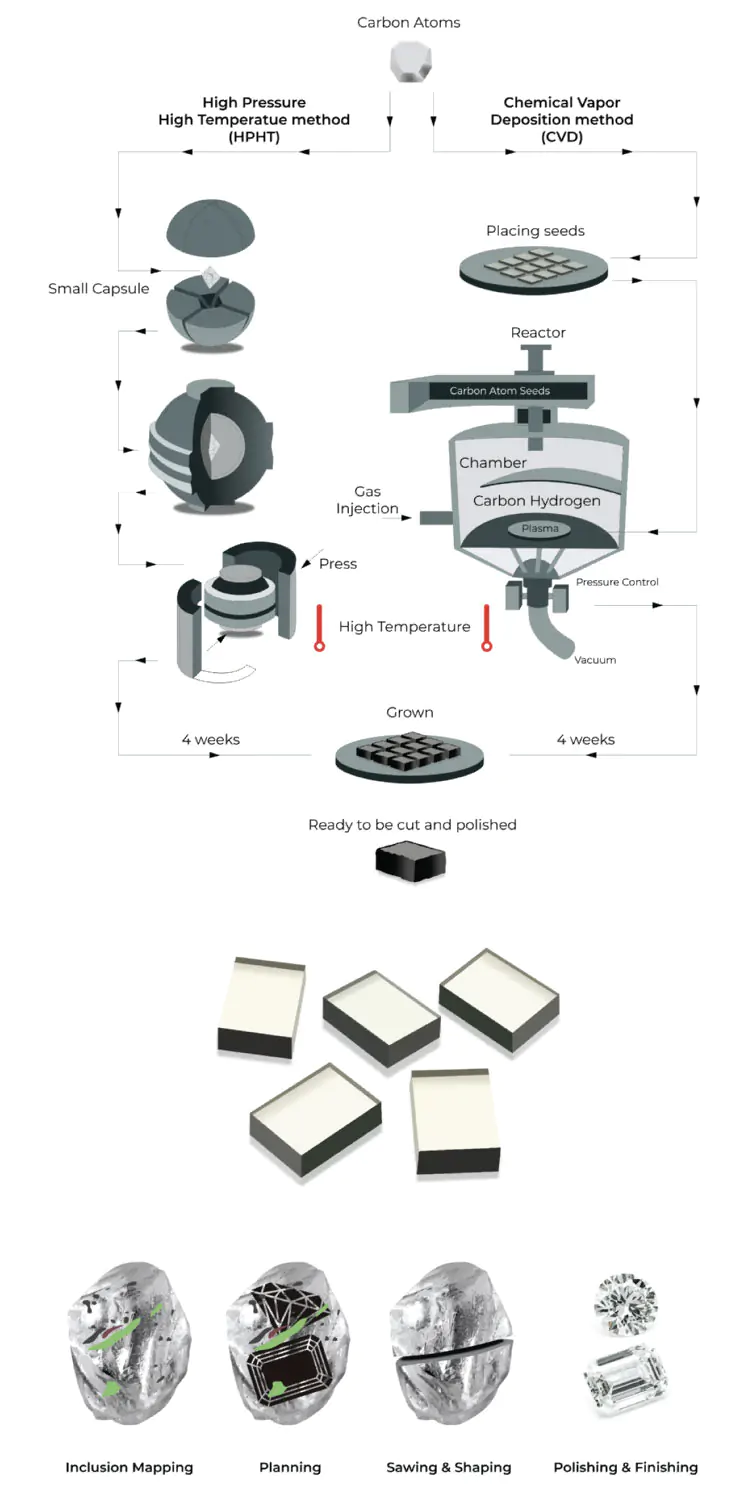

Two main procedures are commonly used to create lab grown diamonds, High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Both methods simulate the earth’s natural processes to create beautiful diamonds in a controlled laboratory setting.

High Pressure High Temperature method (HPHT)

The High Pressure High Temperature (HPHT) diamond production process was first developed in the 1950s for industrial use. While it is most commonly used for creating lab grown diamonds, mined diamonds can also be treated using the HPHT procedure to improve their overall clarity and color.

How are HPHT diamonds made?

The procedure was created to closely resemble the temperature and pressures of the earth’s interior, where natural diamond crystals develop over the course of billions of years. In contrast to the roughly1-3 billion years it takes for natural diamonds to form, the HPHT technique successfully recreates this environment and enables a diamond to form in a matter of weeks!

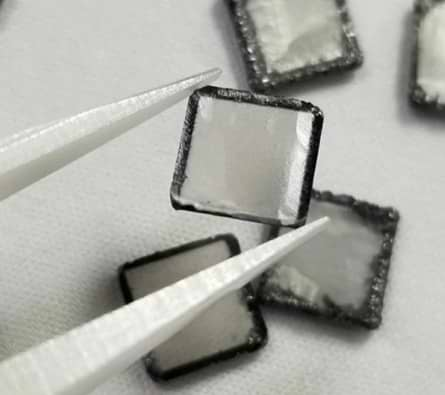

HPHT diamonds are produced using three fundamental manufacturing techniques: the split beer (BARS) press, the cubic press, and the belt press. A little diamond seed enclosed in carbon is placed into each process’s high pressure and temperature environment for several days and as the carbon melts, a diamond is formed around the seed until a full-sized diamond is created.

Chemical Vapor Deposition (CVD)

In this process a diamond is created from a hydrocarbon gas mixture using a recently developed technology called chemical vapor deposition (CVD), which is similar to how diamonds arise in interstellar gas clouds. The CVD procedure, which was developed in the 1980s, is widely seen to be the less expensive way to make diamonds because it uses less energy than HPHT.

How are CVD Diamonds made?

A small slice of diamond seed is heated to a temperature of around 800° degrees Celsius in a sealed container before being filled with other carbon-rich gasses, such as methane.

Microwaves, lasers, and other devices are then used to ionize the gasses and create plasma. The breakdown of the gasses by ionization makes it possible for the carbon to merge with the diamond seed and grow the diamond layer by layer.

Two methods can produce jewelry-quality diamonds: HPHT and CVD.

HPHT is an abbreviation for High Pressure/High Temperature. This method replicates the natural formation of diamonds by subjecting carbon to high temperatures and pressing it together. This expensive process necessitates a significant amount of energy.

CVD is an abbreviation for Chemical Vapor Deposition. A seed crystal chamber is filled with a mixture of hydrogen and methane gas. Microwave power often heats the chamber to a high temperature, which excites the gas. The diamond grows on the seed crystal.

Lab grown diamonds are definitely not even close to being fake diamonds. Historically, false diamonds were usually made of glass. Glass is far less durable and has far less radiance than a well-cut diamond. There are no such problems with lab created diamonds. They are as durable and dazzling as mineral diamonds.

Diamonds created in a laboratory have the same thermal and electrical conductivity as mined diamonds. As a result, they will pass the diamond tester exam.